3.019 LOW c1850 PLA BHM 1736 B27

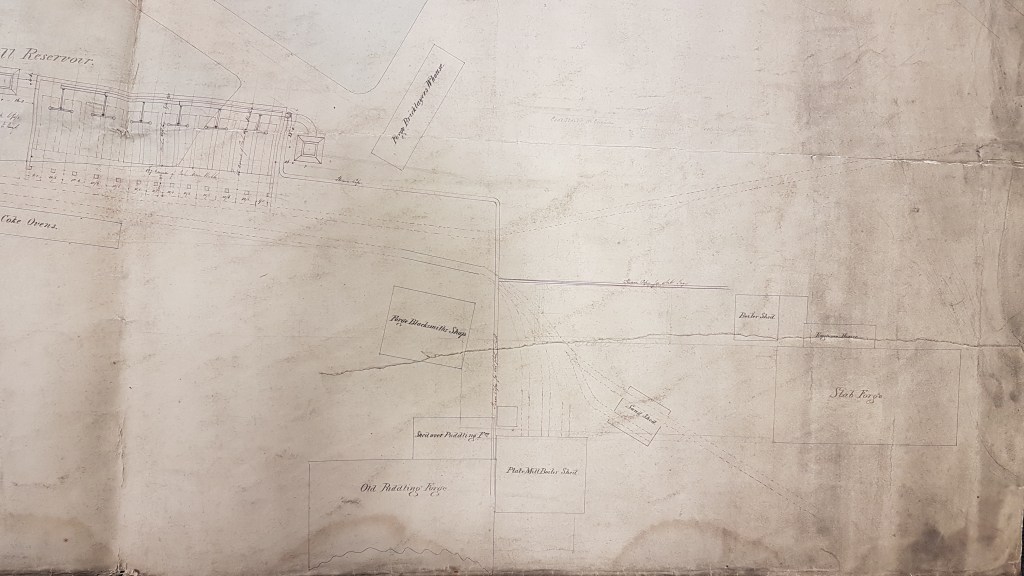

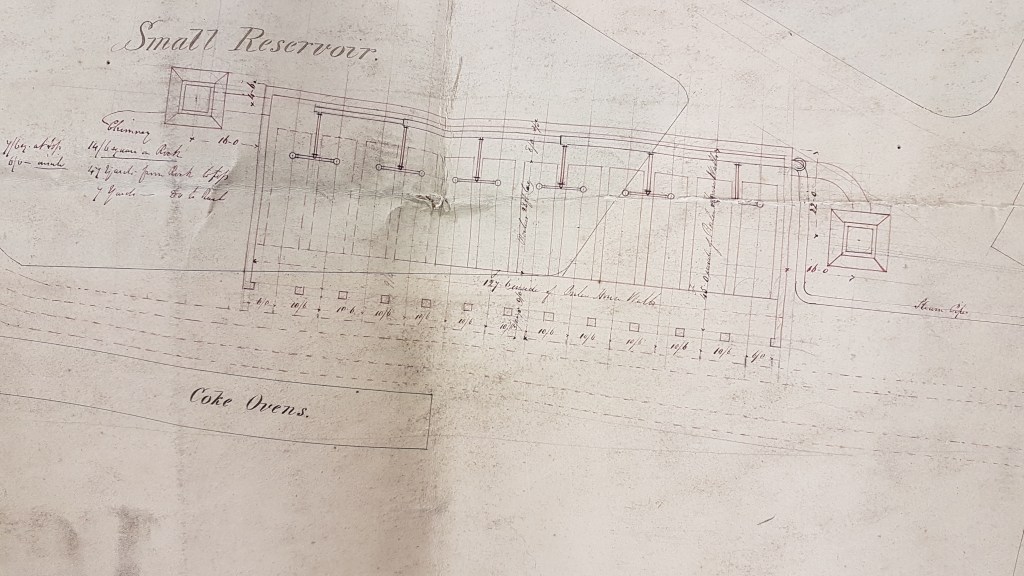

Portion of Low Moor iron works: ‘Plan of Forge Dam’.

Material: paper backed with linen

Scale: unk Size: 200*140 cm Condition: good

Low Moor Iron Works was founded in the 1790s and, despite many vicissitudes, metal processing was still continuing there up to the 1950s but has now ceased. I am surprised that plans of this most important of Bradford industrial concerns are not more common in the Local Studies Library collection and I would propose to record here anything that I can find.

This example is far too large to photograph in its entirety. The name ‘Low Moor’ doesn’t actually appear on the plan but the location adjacent to Huddersfield Road confirms that this was the location. The plan is annotated ‘Forge Dam’ but if this was indeed its original purpose it has subsequently been re-used. In addition to a large & small reservoir the original plan identified the following units: Old Puddling Forge, Coke Ovens, Forge Blacksmith’s Shop-houses, Forge bricklayer’s house, Sand Shed, and a Slab Forge with its boiler shed and engine house.

The whole process of iron production at Low Moor depended on the conversion of Better Bed Coal to coke. Coke was essential as the fuel for smelting iron from iron ore, replacing charcoal for this purpose in the eighteenth century. The production of coke resulted in other useful products such as town gas and coal tar. Puddling was the technique adopted for converting the brittle cast-iron produced in the blast furnaces into ‘wrought iron’ which was stronger and more resistant to corrosion. This has long been replaced by mild steel but in the nineteenth century Best Yorkshire wrought iron produced at Low Moor had a world-wide reputation. A detailed account of iron making at Low Moor is that of Charles Dodsworth in 1971 (Industrial Archaeology, 8, pps. 122-161). He states that a new puddling section was erected in 1846 which suggests that this plan is no earlier than 1850. Forging was the shaping of metal by hammering to shape and is contrasted to casting where liquid metal is poured into a mould. Iron slabs produced in the slab forge are likely to have been incorporated into engine boilers for which there was a huge demand in a steam-driven world.

Additions to the original plan are drawn in red. Clearly a multi-bayed building with two chimneys has been built, or at least designed, over part of the small reservoir. It is not identified a to function, but it is connected by steam pipes to neighbouring buildings. Was its whole purpose steam production? I may need to find another map before I am sure of that.