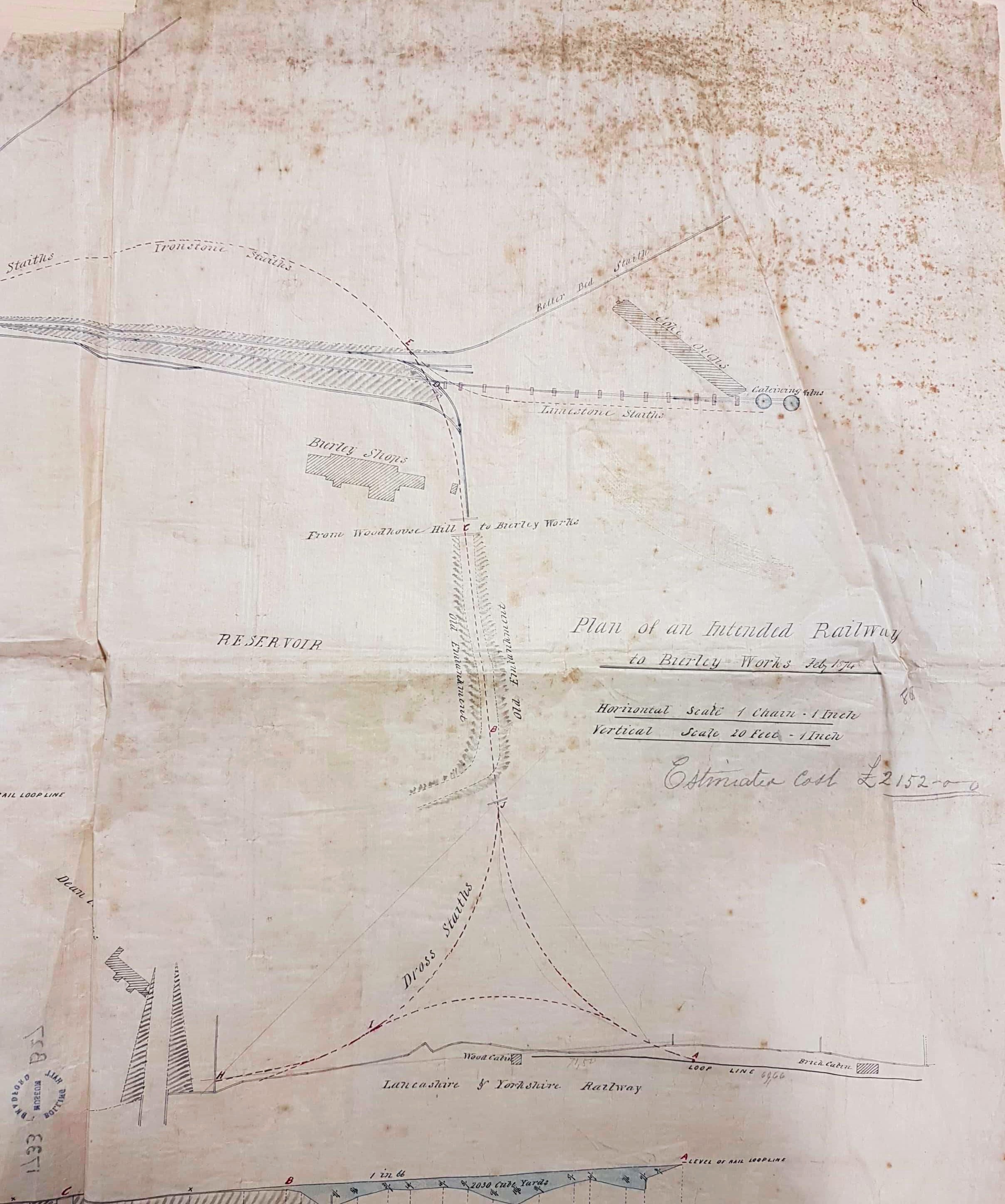

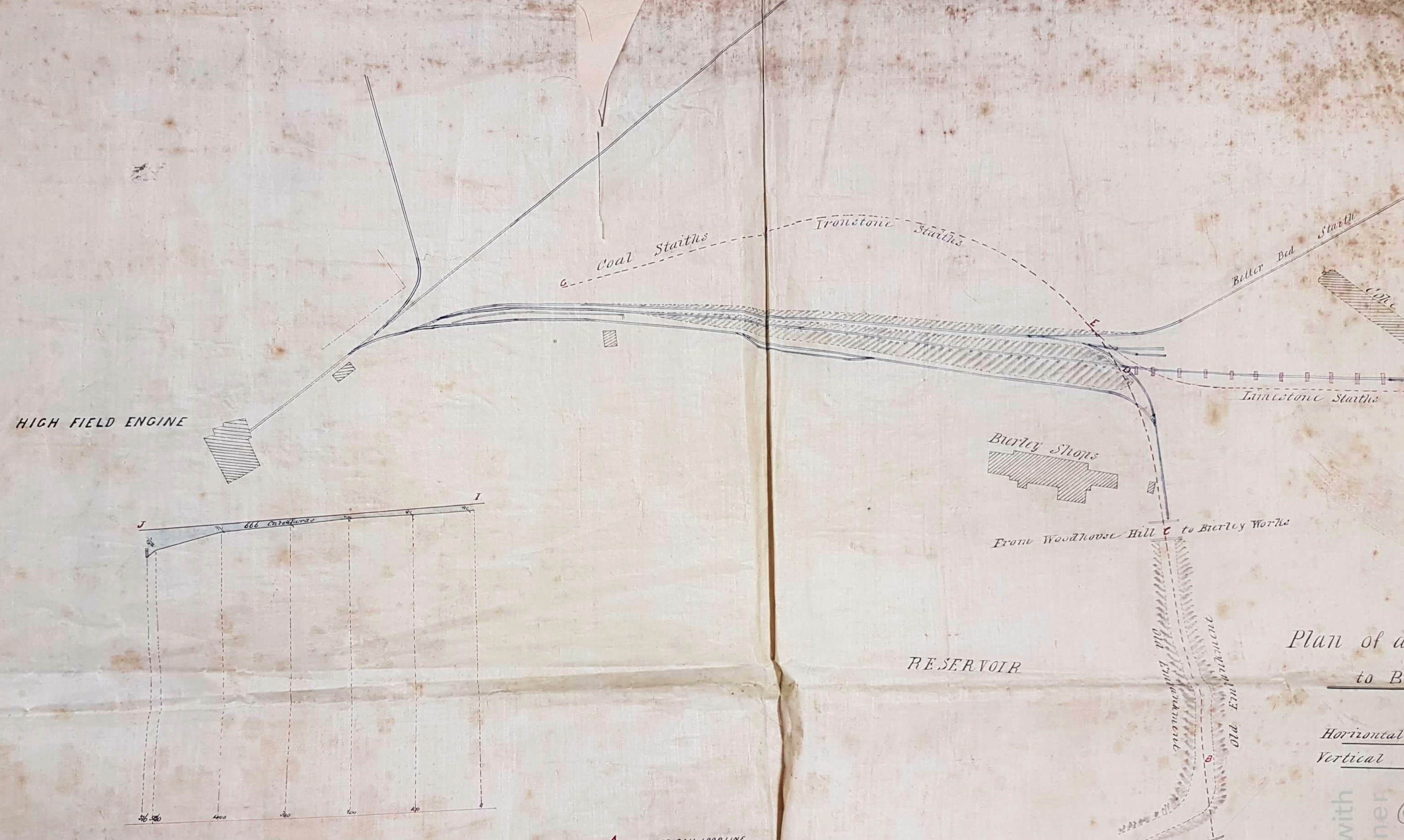

This plan, with west at the top, records an intention to construct a loop line from the Lancashire & Yorkshire Railway, Bradford-Halifax mainline, to service a portion of the Bierley Ironworks, at an estimated cost of £2152. This would pass through an old embankment and round a reservoir. The area involved is immediately east of Wesley Place and the L&YR track involved is just south of Bowling tunnel. An earlier, but anonymous, student of the plan has provided us with a date of 1874 which I have no reason to doubt. The new track arrangements were certainly in place by the time of the 1889 Ordnance Survey 6 inch map. Low Moor Iron Company was founded in 1790. In 1854 it acquired the Bierley Ironworks which until then had enjoyed an independent existence. The new acquisition was integrated with the Low Moor works and stayed in operation for the remainder of the nineteenth century.

The value of this plan lies in the works details recorded: ironstone staithes, coal staithes, Better Bed staithe near to the coke ovens, limestone staithes, and dross staiths. Staithe is a dialect word meaning a storage area or a landing stage for loading or unloading cargo. The fact that the word is found in Yorkshire, Northumberland and Norfolk suggests a Norse origin. In any event these plan details, if properly understood, explain the whole operation of iron smelting blast furnaces in Bradford. A commercially valuable seam of ironstone or iron ore was found in the roof of the Black Bed coal seam which was exploited over much of Bradford and sites on its southern boundaries. A number of blast furnaces were constructed to smelt the ore, the most famous being those of the Bowling Iron and Low Moor Iron Companies. A huge network of mineral tramways were set up by both companies to collect the outputs of the mines they operated. The continuous lines emerging from the High Field Engine on the present plan are examples of such tramways.

The coal from this seam was not considered especially valuable. During the first national coal strike of 1912 the Royds Hall, Low Moor, mine-waste tip was found to contain so much coal (the Low Moor Company at the time of its formation being only interested in the ironstone) that, despite being now covered in trees and grass, miners were getting coal out and selling it to local people at 12s per ton. The Better Bed was a deeper seam of coal which was largely free of impurities like phosphorous and sulphur. It made excellent smelting coke, when destructively distilled in coke-ovens of course. This fuel, which largely consisted of carbon, was used to smelt the iron ore. Treated with an air blast it provided the necessary heat but also the carbon monoxide necessary to create an atmosphere in the furnace which produced molten metallic iron by reducing the iron oxide ore. No blast furnaces are present on this plan: presumably those on the Low Moor site were employed.

Limestone was the third component added to the mix supplied to these blast furnaces; it was available from quarries in Skipton, and elsewhere in the Dales, from which it could be transported by canal and then rail. In the furnace combined with silicate impurities to produce a slag or dross which, when molten, floated on top of the iron and could be tapped off separately. The exact amount of lime required depended on the exact chemical composition of the iron ore. Close to the lime staithes are calcining kilns where the lime (calcium carbonate) could be burned with coke fuel to produce quicklime (calcium oxide). The dross staithes must have been the sites where the cooled slag could sit awaiting removal. In fact so great was the production of slag that dross hills or mountains must have been produced. The glassy material was not without its uses. It could be broken up and used as a hard core foundation for Bradford’s tracks and road ways, where it can still be found today. Nevertheless supply probably greatly exceeded demand. The end product of this whole process were pigs of cast iron. This could be remelted in a puddling furnace to produce the best Yorkshire wrought iron for which Bowling and Low Moor were famous. Wrought iron was subsequently replaced by cheaper and stronger mild steel, and is no longer produced.

The High Field Engine on the plan is simply recorded as ‘engine house’ on the OS map. Aside from these features cottages are marked, also a wood cabin, a brick cabin and ‘Bierley Shops’ – possibly a foundry.